Hardware deg processing tuaj yeem faib ua: hardware oxidation processing, hardware painting processing, electroplating, deg polishing processing, hardware corrosion processing, etc.

Surface processing ntawm hardware qhov chaw:

1. Oxidation processing: lub Hoobkas kho vajtse txais oxidation processing ntawm cov khoom kho vajtse tiav (feem ntau yog txhuas qhov chaw) ua rau saum npoo ntawm cov khoom kho vajtse nyuaj, Ua kom tsis tshua muaj kev hnav.

2. Spray painting processing: lub Hoobkas kho vajtse txais cov tshuaj pleev xim ua haujlwm thaum tsim cov khoom lag luam loj tiav, uas tuaj yeem tiv thaiv cov khoom siv los ntawm xeb, Piv txwv li: cov khoom siv niaj hnub, cov khoom siv hluav taws xob, khoom siv tes ua, thiab lwm yam.

3. Electroplating: electroplating kuj yog cov txheej txheem ntau tshaj plaws rau kev kho vajtse.Qhov saum npoo ntawm cov khoom siv yog electroplated los ntawm cov cuab yeej niaj hnub los xyuas kom meej cov khoom ntev ntev, Tsis muaj mildew lossis embrittlement nyob rau hauv kev siv lub sijhawm.Cov txheej txheem electroplating feem ntau yog: screws, stamping qhov chaw, roj teeb chips, tsheb qhov chaw, me me accessories, thiab lwm yam

4. Nto polishing: nto polishing feem ntau yog siv rau hauv cov khoom siv txhua hnub rau lub sijhawm ntev, thiab cov burrs saum npoo ntawm cov khoom kho vajtse raug kho, xws li: Peb tsim cov zuag.Lub zuag yog ib qho hlau ua los ntawm nias.Cov ces kaum ntawm lub punched zuag yog ntse heev.Peb yuav tsum Sharp npoo thiab cov ces kaum yog polished rau hauv lub ntsej muag du, kom tsis txhob muaj kev puas tsuaj rau tib neeg lub cev thaum siv.

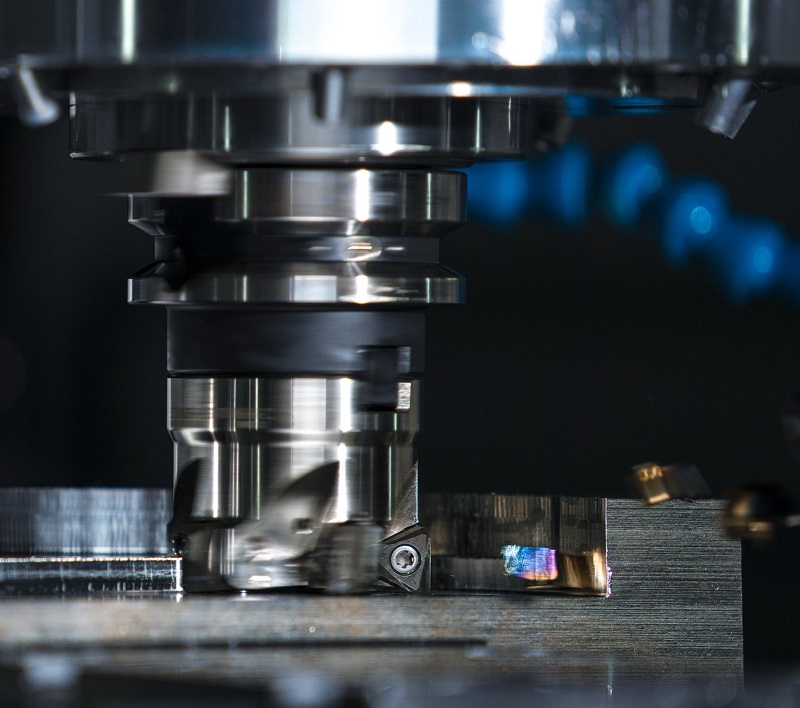

Txoj kev machining ntawm cnc workpiece nto nyob ntawm qhov kev xav tau ntawm lub tshuab ua haujlwm.Txawm li cas los xij, nws yuav tsum tau muab sau tseg tias cov kev cai no tsis yog qhov tseem ceeb

Cov kev cai uas teev nyob rau hauv daim duab yuav siab dua cov nyob rau hauv ib feem ntawm daim duab kos nyob rau hauv ib co yam vim li cas technology.Yog hais tias nws yog nce vim tsis coincidence ntawm datum

Machining xav tau rau saum npoo ntawm qee qhov cnc machined qhov chaw.Los yog nws yuav tso siab rau kev ua tiav ntau dua vim nws suav tias yog kev siv qhov tseeb.

Tom qab cov txheej txheem kev cai rau qhov chaw ntawm CNC machined qhov chaw tau teev tseg, qhov kawg machining txoj kev uas tuaj yeem lav qhov yuav tsum tau xaiv raws li, thiab tus naj npawb ntawm cov kauj ruam thiab cov txheej txheem ntawm txhua kauj ruam.Cov txheej txheem kev xaiv ntawm CNC machining qhov chaw yuav tsum ua tau raws li qhov yuav tsum tau ua ntawm cov khoom zoo, kev lag luam zoo thiab kev ua haujlwm siab ntau lawm.

Vim li no, cov hauv qab no yuav tsum tau txiav txim siab thaum xaiv txoj kev ua:

1. Lub machining raug thiab nto roughness tau los ntawm tej CNC machining txoj kev muaj ib tug ntau yam, tab sis tsuas yog nyob rau hauv ib tug nqaim range.Qhov ntau ntawm yog economic, thiab machining raug ntawm no ntau yam yog economic machining raug.Yog li ntawd, thaum xaiv cov txheej txheem ua, tus coj.Cov txheej txheem ua haujlwm uas tuaj yeem tau txais kev lag luam ua tiav precision.

2. Cov khoom ntawm CNC machining cov ntaub ntawv yuav tsum tau txiav txim siab.

3. Cov qauv tsim thiab qhov loj ntawm CNC machined qhov chaw yuav tsum raug txiav txim siab.

4. Kev tsim khoom thiab kev lag luam yuav tsum raug txiav txim siab.High efficiency thiab advanced technology yuav tsum tau saws rau loj ntau lawm.Nws tuaj yeem hloov pauv qhov khoob.Qhov kev tsim khoom tuaj yeem txo cov nqi zog hauv machining.

5. Cov khoom siv uas twb muaj lawm thiab kev ua haujlwm ntawm lub Hoobkas lossis kev cob qhia yuav tsum raug txiav txim siab.Thaum xaiv cov txheej txheem ua tiav, cov khoom siv uas twb muaj lawm yuav tsum tau siv tag nrho los siv lub peev xwm ntawm kev lag luam.Qhov kev txaus siab thiab kev muaj tswv yim ntawm cov neeg ua haujlwm.Txawm li cas los xij, kev txhim kho txuas ntxiv ntawm cov txheej txheem thiab cov khoom siv uas twb muaj lawm, kev siv cov thev naus laus zis tshiab thiab kev txhim kho cov txheej txheem yuav tsum tau txiav txim siab.

Post lub sij hawm: Oct-08-2022