Burrs ntawm qhov chaw yog qhov txaus ntshai heev: ua ntej, nws yuav ua rau muaj kev pheej hmoo ntawm tus kheej raug mob;Thib ob, nyob rau hauv cov txheej txheem downstream, nws yuav ua rau muaj kev phom sij rau cov khoom zoo, cuam tshuam rau kev siv cov khoom siv thiab txawm tias luv luv lub neej kev pab cuam ntawm cov khoom siv.Hauv tsab xov xwm no, peb yuav qhia txog yuav ua li cas siv cov cuab yeej deburring siab heev kom tshem tawm cov burrs, pab koj txo cov nqi tsim khoom thiab txhim kho kev ua haujlwm.

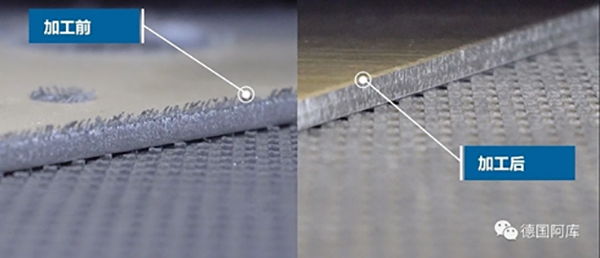

Txawm hais tias xuas nrig ntaus, laser txiav lossis plasma txiav, cov txheej txheem machining yuav tsim cov npoo ntse thiab burrs ntawm qhov chaw.Tshwj xeeb tshaj yog thaum lub sij hawm plasma txiav, slag (sib tov ntawm oxides thiab hlau residues) yuav tawv ncauj tso rau ntawm ntug ntawm ib feem.Txawm hais tias txiav txoj kev twg yog txais, nws yog ib qho tseem ceeb heev rau deburr ntau yam tom qab txiav.Cov laj thawj yog raws li nram no:

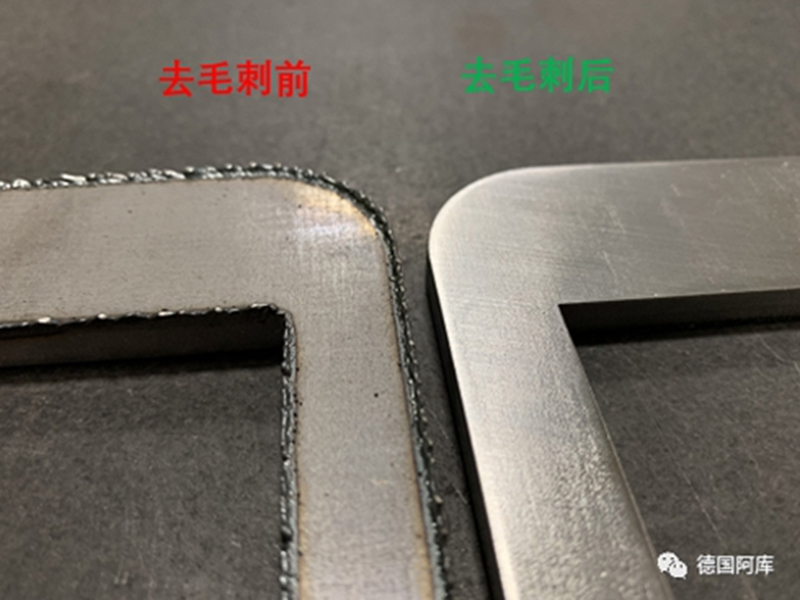

1. Deburring tuaj yeem txo qhov kev pheej hmoo ntawm kev raug mob

Cov npoo ntse thiab burrs yog qhov txaus ntshai heev, thiab cov neeg ua haujlwm tau yooj yim khawb thaum lub sijhawm ua haujlwm, uas yuav cuam tshuam rau kev ua haujlwm zoo ntawm kev ua haujlwm loj.Ntawm ib sab, ntxiv cov txheej txheem deburring thiab rounding tuaj yeem txhim kho kev nyab xeeb ntawm qhov chaw ua haujlwm thiab txo tus nqi qis;Ntawm qhov tod tes, nws tuaj yeem ua kom muaj kev nyab xeeb ntawm cov neeg ua haujlwm hauv txhua qhov txheej txheem ntawm cov saw hlau ntau lawm, thiab kev pheej hmoo ntawm tus kheej raug mob yuav luag xoom.

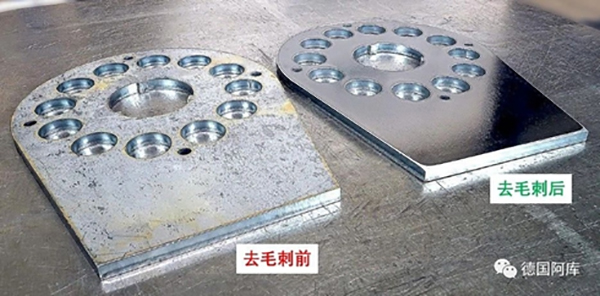

2. Deburring tuaj yeem txhim kho cov khoom zoo

Burrs tsis yog tsuas yog txaus ntshai rau tib neeg, tab sis kuj rau cov cuab yeej thiab tshuab.Piv txwv li, lub tshuab bending lossis roller leveler, yog tias qhov chaw ntawm cov tshuab no feem ntau hu rau cov npoo ntse thiab burrs ntawm cov khoom siv, qhov hnav yuav nrawm dua, thiab cov teeb meem loj yuav ncaj qha mus rau qhov chaw nres tsheb thiab siv tsis tau.Yog li ntawd, deburring thiab rounding ntawm qhov chaw yog ib qho tseem ceeb rau kev tiv thaiv cov cuab yeej thiab tshuab, ncua lawv cov kev pab cuam lub neej thiab txo nqi txij nkawm.

3. Phau ntawv deburring tau mus txog qhov kev txwv nyiaj txiag

Thaum deburring machined qhov chaw, ntau lub lag luam tseem cia siab rau kev siv phau ntawv.Piv txwv li, cia qee tus neeg ua haujlwm paub txog siv txhuam los yog lub kaum sab xis kom tshem tawm cov npoo, burrs thiab splashes.Qhov zoo ntawm txoj kev no yog tias nws tuaj yeem saib xyuas seb qhov chaw ntawm qhov chaw puas puas los yog tsis.Nws tuaj yeem kuaj pom qhov tshwm sim ntawm ntu thiab ua qhov kev txiav txim ua ntej thaum tshem tawm cov burr.Yog tias muaj khawb, nws tuaj yeem khaws, kho lossis rov ua dua.

Post lub sij hawm: Feb-21-2023