Hardware surface processing can be subdivided into: hardware oxidation processing, hardware painting processing, electroplating, surface polishing processing, hardware corrosion processing, etc.

Surface processing of hardware parts:

1. Oxidation processing: the hardware factory adopts oxidation processing on the finished hardware products (mainly aluminum parts) to make the surface of the hardware products hard, Make it less susceptible to wear.

2. Spray painting processing: the hardware factory adopts spray painting processing when producing large hardware finished products, which can prevent the hardware from rusting,For example: daily necessities, electrical enclosures, handicrafts, etc

3. Electroplating: electroplating is also the most common processing technology for hardware processing. The surface of hardware is electroplated through modern technology to ensure long product length,There is no mildew or embrittlement under the use of time. The common electroplating processes are: screws, stamping parts, battery chips, car parts, small accessories, etc

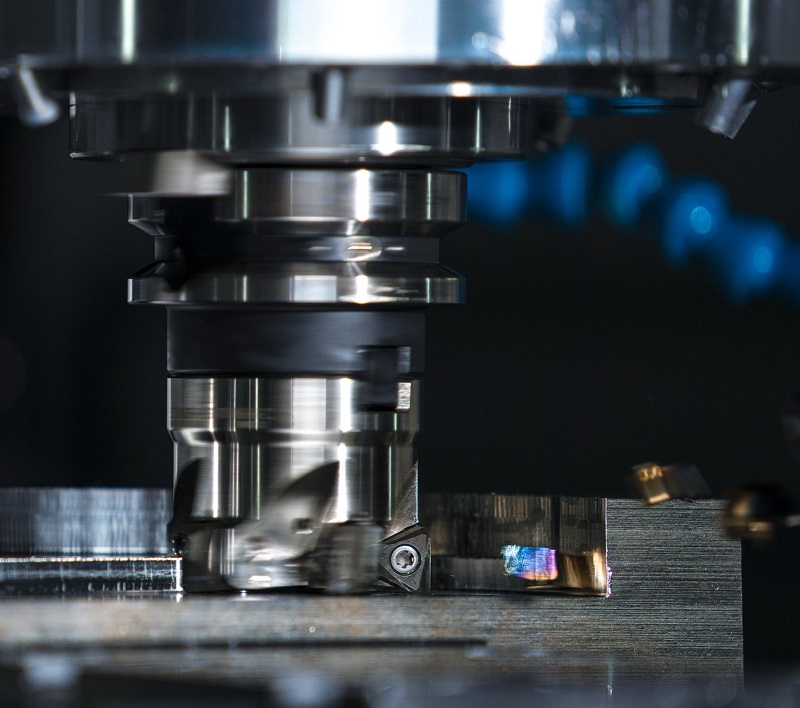

4. Surface polishing: surface polishing is generally used in daily necessities for a long time, and the surface burrs of hardware products are treated, such as:We produce a comb. The comb is a metal part made by pressing. The corners of the punched comb are very sharp. We need to Sharp edges and corners are polished into smooth face, so that no harm will be caused to human body during use.

The machining method of cnc workpiece surface depends on the technical requirements of the machined surface. However, it should be noted that these technical requirements are not necessarily parts

The requirements specified in the drawing may be higher than those on the part drawing in some aspects due to technological reasons. If it is increased due to non coincidence of datum

Machining requirements for the surface of some cnc machined parts. Or it may put forward higher processing requirements because it is regarded as precision reference.

After the technical requirements for the surfaces of CNC machined parts are specified, the final machining method that can guarantee the requirements can be selected accordingly, and the number of steps and processing methods of each step. The selected processing method of CNC machining parts should meet the requirements of parts quality, good processing economy and High production efficiency requirements.

For this reason, the following factors should be considered when selecting the processing method:

1. The machining accuracy and surface roughness obtained by any CNC machining method have a considerable range, but only in a narrow range.The range of is economic, and the machining accuracy of this range is economic machining accuracy. Therefore, when selecting the processing method, the corresponding.The processing method that can obtain economic processing precision.

2. The properties of CNC machining materials shall be considered.

3. The structural shape and size of CNC machined parts shall be considered.

4. Productivity and economy requirements shall be considered. High efficiency and advanced technology shall be adopted for mass production. It can even fundamentally change the blank.The manufacturing method can reduce the amount of labor in machining.

5. The existing equipment and technical conditions of the factory or workshop shall be considered. When selecting the processing method, the existing equipment shall be fully used to tap the potential of the enterprise.The enthusiasm and creativity of workers. However, continuous improvement of existing processing methods and equipment, adoption of new technologies and improvement of process level should also be considered.

Post time: Oct-08-2022