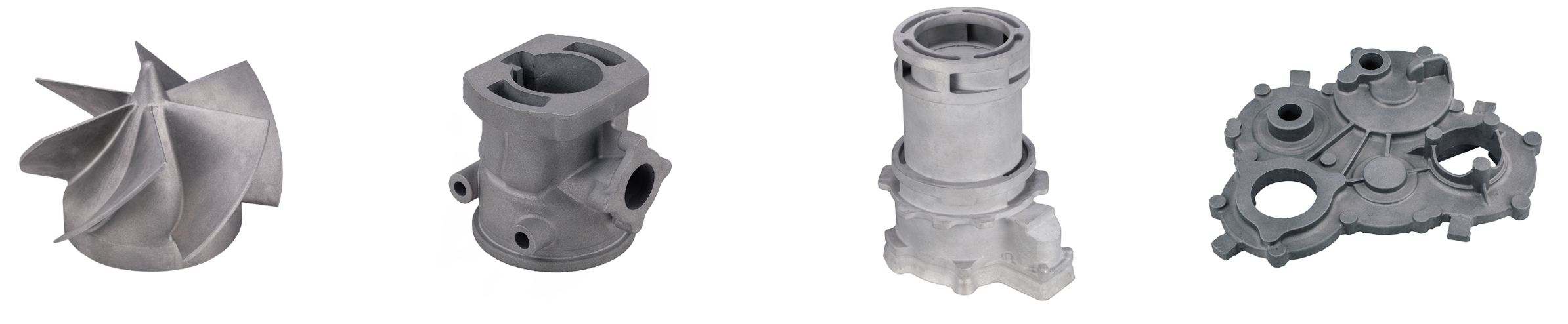

Maitiro/Equipment Display

Surface Treatment

Kurapa kwepamusoro inzira yekugadzira dhizaini repamusoro pamusoro peiyo substrate zvinhu zvakasiyana kubva kumakanika, zvemuviri uye zvemakemikari zvimiro zve substrate.Chinangwa chekurapa kwepamusoro ndechekusangana nekushomeka kwecorrosion, kupfeka kuramba, kushongedza kana zvimwe zvakakosha zvinoshanda zvechigadzirwa.Kune masimbi castings, isu tinonyanya kushandiswa pamusoro pekurapa nzira ndeye mechanical polishing, chemical treatment, surface heat treatment, spraying the surface, kuchenesa, kubvisa, deburring, deoxide, etc. pamusoro pe workpiece.

Electrolysis

Electrolysis inzira umo kugadzirwa kwekemikari yezvinhu zvakakwirira-kuchena uye kugadzirwa kwepamusoro pezvinhu kunoitwa nemaitiro e electrochemical anoitika pakusangana pakati pe electrode seyemagetsi conductor uye electrolyte seion conductor.

Kupukuta

Kupukuta kunoreva kushandiswa kwemakanika, kemikari kana electrochemical chiito kudzikisa kushata kwepamusoro kwechishandiso kuti uwane inopenya uye yakatsetseka pamusoro pekugadzirisa nzira.Iko kushandiswa kwezvishandiso zvekupolisha uye abrasive particles kana imwe polishing media kugadzirisa pamusoro peiyo workpiece.

Sandblasting

Iyo sandblasting process inoshandisa mhepo yakamanikidzwa sesimba rekugadzira yakakwira-speed jet danda, uye inopfapfaidza zvinhu zvekupfapfaidza kumusoro kweiyo workpiece kuti igadziriswe nekukurumidza, kuitira kuti kutaridzika kwekunze kweiyo workpiece kuchinje.Pamusana pekugadzirisa uye kucheka kwekucheka kweabrasive pamusoro pebasa rekushanda, pamusoro pebasa rekushanda Tora imwe dhigirii yehutsanana uye hutsinye hwakasiyana, kuitira kuti mashizha emagetsi ebasa rekushanda avandudzwe.

Oxidation

Oxidation inoreva kugona kwechinhu kuwana maerekitironi.Zvinhu zviri munzvimbo yakakwirira yevalence uye zvinoshanda zvisiri zvesimbi (senge fluorine, chlorine, oxygen, nezvimwewo) zvinowanzoita oxidizing.Iyo oxidation kurapwa kwesimbi ndiko kudyidzana kwesimbi pamusoro neokisijeni kana oxidant kuumba inodzivirira oxide firimu kudzivirira simbi corrosion.

Electroplating

Electroplating mushonga wesimbi wepamusoro unosanganisira kupfekedza chidimbu chakatetepa cheimwe simbi kana simbi alloy pane chikamu chesimbi kudzivirira ngura uye oxidation yeworkpiece, kana kushandura chimiro chayo.Tin, nickel, zingi (galvanized) uye chromium zvese zvakajairika electroplating simbi, nepo mhangura nekabhoni simbi ndidzo simbi mbiri dzinowanzo shandisa maitiro e electroplating.

Laser Carving

Laser engraving ndeyekuita chaiwo uye zvisingaperi mamaki pasimbi uye mamwe mapurasitiki.

Sanding

Kukuya nemaoko kunogona kubvisa machining mamaki, kubvisa maburrs pamusoro pezvikamu, mitsetse yekugadzira uye adhesion mamaki uye zvimwe zvinokanganisa zvigadzirwa.Iyo flatness yezvikamu ichagadziridzwa uye iyo roughness ichaderedzwa kuti iwane yakatsetseka uye inowirirana chitarisiko chepamusoro.

Zvigadzirwa zvikamu

-

wechat

-

Whatsapp

whatsapp