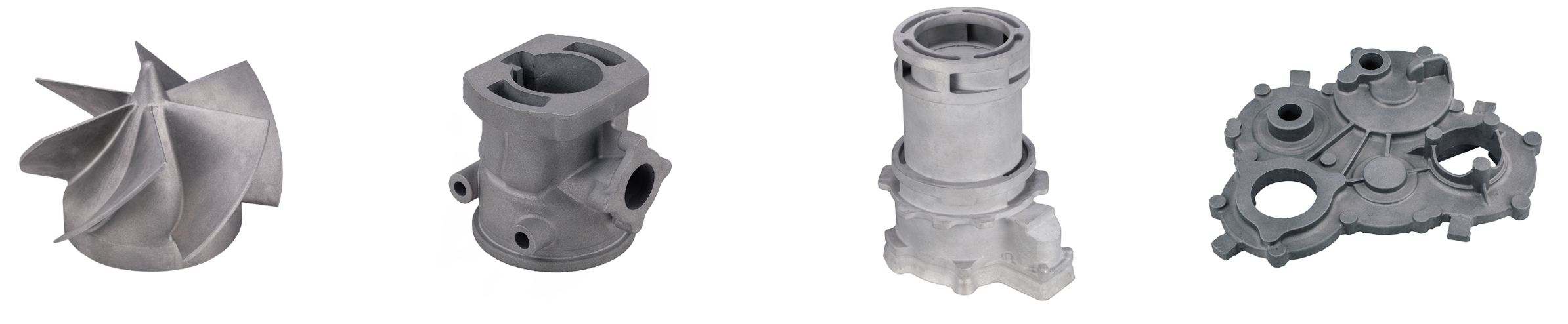

Habka/ Bandhiga Qalabka

Daaweynta Dusha sare

Daawaynta dusha sare waa nidaam si macmal ah loogu samaynayo lakabka dusha sare ee maaddada substrate-ka oo ka duwan qalabka farsamada, jirka iyo kiimikaad ee substrate-ka.Ujeedada daaweynta dusha sare waa in la daboolo caabbinta daxalka, xirashada caabbinta, qurxinta ama shuruudaha kale ee gaarka ah ee alaabta.Biraha wax lagu shubo, waxaanu si caadi ah u isticmaalnaa hababka daawaynta dusha sare ee farsamada, daaweynta kiimikada, daaweynta kulaylka dusha sare, buufinta dusha sare, daawaynta dusha sare waa in la nadiifiyo, nadiifiyo, deburring, dereasing, deoxide, iwm dusha sare ee workpiece.

Electrolysis

Electrolysis waa habka isku-dhafka kiimikaad ee walxaha nadiifka sare ah iyo daawaynta dusha maadada ay fuliyaan fal-celinta elektiroonigga ah ee ka dhacaya isdhexgalka u dhexeeya elektaroonigga sida kaari elektaroonig ah iyo electrolyte ahaan sida aon.

shaandhaynta

Polishing waxaa loola jeedaa isticmaalka farsamo, kiimiko ama fal electrochemical si loo yareeyo roughness dusha workpiece si aad u hesho hab dhalaalaysa oo siman dusha processing.Waa isticmaalka qalabka wax-soo-saarka iyo walxaha wax-soo-saarka ama warbaahinta kale si loo beddelo dusha sare ee shaqada.

Ciid-qarxinta

Habka bacaad-qarxinta waxay isticmaashaa hawo isku-duuban oo ah awoodda si ay u samayso laydh jet-xawaaraha sare leh, waxayna ku buufisaa walxaha buufinta dusha sare ee shaqada si loogu farsameeyo xawaare sare, si muuqaalka dusha sare ee shaqada uu is beddelo.Sababo la xiriira saamaynta iyo goynta saamaynta abrasive ee dusha sare ee workpiece, dusha workpiece Hesho darajo gaar ah oo nadaafadda iyo qalafsanaan kala duwan, si sifooyinka farsamo ee dusha workpiece la hagaajiyo.

Oxidation

Oxidation waxaa loola jeedaa awoodda walaxda si ay u helaan electrons.Walxaha ku jira xaalad valence sare ah iyo walxaha aan birta ahayn ee firfircoon (sida fluorine, chlorine, oxygen, iwm.) ayaa guud ahaan oksaydheynaya.Daaweynta oksaydhka ee biraha waa is dhexgalka dusha birta leh oksijiin ama oksidanti si loo sameeyo filim oksidheer ilaalin ah si looga hortago daxalka birta.

Korantada

Electroplating waa daawaynta dusha birta ah taas oo ku lug leh dahaadh aad u khafiif ah oo bir kale ah ama daawaha birta qayb bir ah si looga hortago daxalka iyo oksaydhka ee workpiece, ama si ay u beddelaan muuqaalkiisa.Tin, nikkel, zinc (galvanized) iyo chromium dhamaantood waa biraha elektiroonigga ah ee caadiga ah, halka naxaasta iyo birta kaarboon ay yihiin labada bir ee ugu badan ee isticmaala hababka korantada.

Xardho Laser ah

xaradhka Laser waa in lagu sameeyo calaamado sax ah oo joogto ah biraha iyo balaastikada qaarkood.

Ciidda

shiididda gacanta waxay ka saari kartaa calaamadaha mishiinka, baabi'inta burooyinka dusha sare ee qaybaha, khadadka wax soo saarka iyo calaamadaha dhejiska iyo cilladaha kale ee alaabta.Baaxadda qaybaha waa la hagaajin doonaa oo qallafsanaanta waa la dhimi doonaa si loo gaaro muuqaal siman oo joogto ah.

Qaybaha alaabta

-

wechat

-

Whatsapp

whatsapp