Litlhoko tsa tloaelo bakeng sa tlhahiso ea liteko likarolong tsohle tsa bophelo

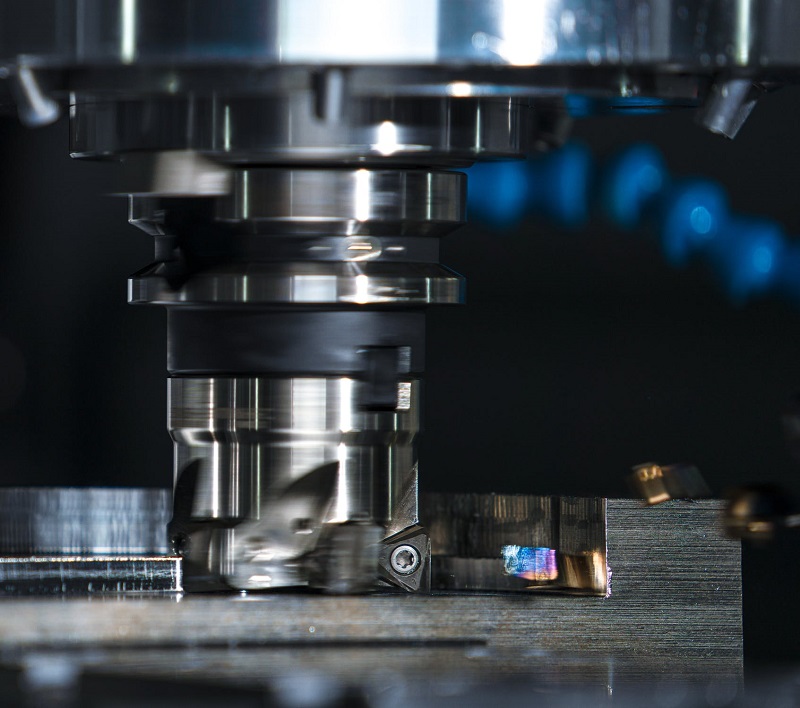

Litheknoloji tse fapaneng tsa ts'ebetso le mahlale a kalafo a holim'a metsi a kenyelletsang likarolo tsa tšepe le polasetiki li kopana le litlhoko tse fapaneng tsa tlhahiso ea liteko le likarolo tsa tlhahiso ea likarolo likarolong tsohle tsa bophelo, ho kenyeletsoa ts'ebetso ea likarolo tsa CNC, ho etsa ente e potlakileng, tšepe ea lakane, ho penta, oxidation, ho fafatsa phofo, electroplating, jj. .

Ho tloha ho ts'ebetso ea boto ea letsoho ea CNC ho isa ho tlhophiso e nyane ea batch

Ho tloha sengoathoana se le seng ho isa ho sekotoana sa 10000, re fana ka litharollo tse fapaneng tsa ho sebetsana le likarolo ho fihlela lintlha tsa hau hantle.Ha o hloka ho tlisa likarolo tse ikhethileng ka nako e khuts'oane, re ka fana ka tšehetso ea boenjiniere ntle le lithibelo.

Tsamaiso ea ts'ebetso ea tlhahiso e feto-fetohang le e sebetsang hantle

Ts'ebetsong ea mekhoa e metle ea tlhahiso, tsamaiso ea merero ea litsebi le sehlopha sa boenjiniere ba litsebi tsa theknoloji, ho tloha ho litlhahiso tsa ho ntlafatsa moralo ho ea ho ntlafatso ea ts'ebetso ea tlhahiso ho finyella katleho e phahameng le boleng bo phahameng, le ho tsoela pele ho ntlafatsa khotsofalo ea bareki.

Fumana Melemo ea ho Itloaetsa Mechine ea CNC bakeng sa Likarolo Bakeng sa Hau

Ts'ebetso ea likarolo tsa CNC e kopana le lintlha tsa hau tse thata

CNC Mechine ea Metal Parts

Motsoako oa Ts'ebetso ea Motsoako oa Lisebelisoa tsa Tšehetso

Fana ka mefuta e mengata e fapaneng ea machining ea CNC ea lisebelisoa tsa tšepe, ho kenyeletsoa motsoako oa aluminium, alloy ea magnesium, alloy ea zinki, alloy ea titanium, tšepe e sa hloekang, joalo-joalo, e tšehetsang bokhoni ba ho fetola le ho sila machining a kopantsoeng, ho fana ka ts'ebetso e nepahetseng ka ho fetesisa le bokhoni ba ho nepahala. ho lokisa likarolo.

CNC Mechine ea Likarolo tsa Plastiki

Tharollo e Ikemetseng ea Handboard Processing

CNC machining ea lipolasetiki tsa sehlopha sa boenjiniere tse fetang 30, ho tloha mefuteng ea meralo ea pono ho ea ho liboto tse sebetsang tsa matsoho, re tsepamisitse maikutlo ho machining likarolo tsa polasetiki tse nang le bokaholimo le meaho e kobehileng, ho etsa phetheho, mamello e phahameng, ponaletso ea optical, le mekhoa e fapaneng ea kalafo ea bokaholimo bakeng sa hau.