Ukusetyenzwa komphezulu we-Hardware kunokohlulwa ibe: i-hardware oxidation processing, i-hardware yokupeyinta, i-electroplating, i-face polishing processing, i-hardware corrosion processing, njl.

Ukusetyenzwa komphezulu kwamalungu ehardware:

1. Ukulungiswa kwe-oxidation: i-factory ye-hardware ithatha i-oxidation processing kwiimveliso ze-hardware ezigqityiweyo (ikakhulukazi iinxalenye ze-aluminium) ukwenza umphezulu weemveliso ze-hardware zibe nzima, Yenza kube lula ukunxiba.

2. Ukutshiza ukupeyinta ukupeyinta: umzi-mveliso we-hardware wamkela inkqubo yokupeyinta yokutshiza xa uvelisa i-hardware enkulu egqityiweyo, enokuthintela i-hardware ukuba ingarusa, Umzekelo: iimfuno zemihla ngemihla, iingcingo zombane, imisebenzi yezandla, njl.

3. I-Electroplating: I-electroplating nayo yeyona ndlela ixhaphakileyo yokucubungula iteknoloji ye-hardware processing.Umphezulu we-hardware i-electroplated ngokusebenzisa itekhnoloji yanamhlanje ukuqinisekisa ubude bemveliso emide, akukho mkungu okanye ukugquma phantsi kokusetyenziswa kwexesha.Iinkqubo eziqhelekileyo ze-electroplating zezi: izikrufu, iinxalenye zesitampu, iitshiphusi zebhetri, iinxalenye zemoto, izixhobo ezincinci, njl

4. Ukupholishwa komphezulu: ukucocwa komphezulu kusetyenziswa ngokubanzi kwiimfuno zemihla ngemihla ixesha elide, kwaye i-surface burrs yeemveliso ze-hardware ziphathwa, ezifana: Sivelisa ikama.Ikama yinxalenye yentsimbi eyenziwe ngokucinezela.Iikona zekama elihlatyiweyo zibukhali kakhulu.Kufuneka ukuba ii-Edges ezibukhali kunye neekona zigudiswe zibe bubuso obugudileyo, ukuze kungabikho kwenzakala emzimbeni womntu ngexesha lokusetyenziswa.

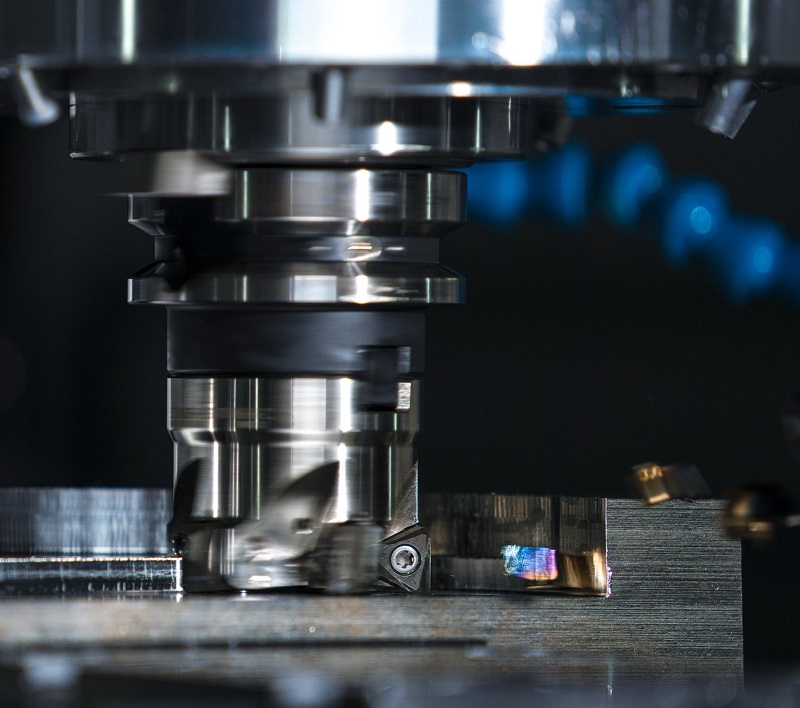

Indlela ye-machining ye-cnc workpiece surface ixhomekeke kwiimfuno zobugcisa bomgangatho owenziwe ngomatshini.Nangona kunjalo, kufuneka kuqatshelwe ukuba ezi mfuno zobugcisa azikho iinxalenye

Iimfuno ezichazwe kumzobo zinokuba phezulu kunezo ziyinxalenye yomzobo kwezinye iinkalo ngenxa yezizathu zobuchwepheshe.Ukuba yonyuswa ngenxa yokungadibananga kwedatum

Iimfuno zokutshiza kumphezulu wezinye iindawo ezinomatshini we-cnc.Okanye inokubeka phambili iimfuno zokuqhubekeka eziphezulu kuba ithathwa njengereferensi echanekileyo.

Emva kweemfuno zobugcisa kwiindawo ze-CNC ezixutywe ngomatshini zichazwe, indlela yokugqibela yokucoca enokuqinisekisa iimfuno inokukhethwa ngokufanelekileyo, kunye nenani lamanyathelo kunye neendlela zokucubungula zenyathelo ngalinye.Indlela ekhethiweyo yokusetyenzwa kwamacandelo omatshini e-CNC kufuneka ihlangabezane neemfuno zomgangatho wamacandelo, uqoqosho olulungileyo lokuqhuba kunye neemfuno eziPhezulu zemveliso.

Ngenxa yesi sizathu, ezi zinto zilandelayo kufuneka ziqwalaselwe xa ukhetha indlela yokucubungula:

1. Ukuchaneka komatshini kunye noburhabaxa bomphezulu obufunyenwe yiyiphi na indlela ye-CNC yomatshini inoluhlu olubanzi, kodwa kuphela kuluhlu olumxinwa.Uluhlu lwezoqoqosho, kwaye ukuchaneka komatshini kolu luhlu kukuchaneka kwezoqoqosho.Ngoko ke, xa ukhetha indlela yokucubungula, indlela ehambelanayo.Indlela yokucubungula enokufumana ukuchaneka kwezoqoqosho.

2. Iipropathi zezixhobo zomatshini ze-CNC ziya kuqwalaselwa.

3. Ubume besakhiwo kunye nobukhulu beendawo zomatshini we-CNC ziya kuqwalaselwa.

4. Iimfuno zemveliso kunye noqoqosho ziya kuqwalaselwa.Ubuchule obuphezulu kunye nobuchwephesha obuphambili buya kwamkelwa ukuveliswa ngobuninzi.Inokutshintsha ngokusisiseko indawo engenanto.Indlela yokuvelisa inokunciphisa inani labasebenzi kumatshini.

5. Izixhobo ezikhoyo kunye neemeko zobugcisa zomzi-mveliso okanye iworkshop ziya kuqwalaselwa.Xa ukhetha indlela yokucubungula, izixhobo ezikhoyo ziya kusetyenziswa ngokupheleleyo ukubetha amandla eshishini. Inzondelelo kunye nobuchule babasebenzi.Nangona kunjalo, ukuphuculwa okuqhubekayo kweendlela zokusetyenzwa kunye nezixhobo ezikhoyo, ukwamkelwa kobuchwepheshe obutsha kunye nokuphuculwa kwenqanaba lenkqubo kufuneka kuthathelwe ingqalelo.

Ixesha lokuposa: Oct-08-2022