Izingxenye zePlastiki zemishini nezinkonzo zokukhiqiza

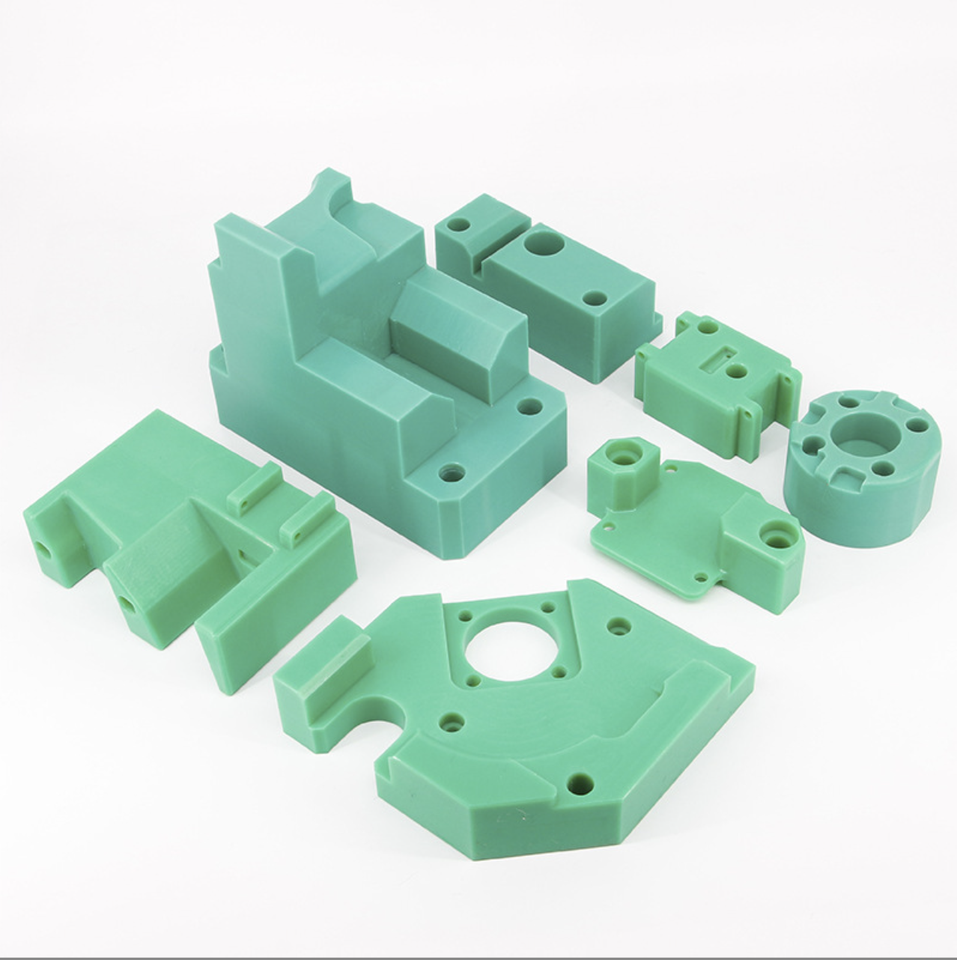

Enqubweni yokuthuthukiswa komkhiqizo omusha, ukucutshungulwa kwepulasitiki ye-CNC kungasetshenziswa uma udinga ukuqinisekiswa kwesibonelo sepulasitiki esikhundleni sezinto eziphrintiwe ze-3D.Ngokusebenzisa lobu buchwepheshe bokucubungula ibhodi lezandla, asikwazi nje ukwenza amamodeli anengqondo ezingxenye zepulasitiki kanye nezingxenye eziqondile zokusebenza, kodwa futhi sinikeze isisombululo esiphelele sokukhiqiza kanye nezidingo zokukhiqiza ze-batch machining encane.

Singasebenzisa izinto zokwakha ezingaphezu kuka-30 ukuze senze izingxenye zemishini yepulasitiki ye-CNC yekhwalithi ephezulu, futhi sisebenzise izindlela zemishini ye-CNC ye-5-eksisi nezinye izinqubo ukuze sakhe ukunemba okuphezulu kokusebenza kwemishini yamapulasitiki obunjiniyela.Ukuqoqwa kwethu ekucutshungulweni kwepulasitiki kusenza sikwazi ukwenza ngokwezifiso izingxenye zakho zepulasitiki ngokwezidingo zakho zesicelo.

Kungani i-GEEKEE's CNC Plastic Processing

Ngesitifiketi se-ISO9001, inqubo yokulawula ikhwalithi ethuthukisiwe ihlangabezana futhi idlule izindinganiso zomkhakha.Siphinde sibe nomnyango ophelele wokuqinisekisa ikhwalithi kanye nonjiniyela bekhwalithi abaqeqeshiwe.

Sinemishini yokukhiqiza ye-CNC ethuthukisiwe engakwazi ukuphatha noma yiluphi uhlobo lwephrojekthi.Amandla ethu okucubungula aphelele afaneleka kakhulu kumaphrojekthi epulasitiki epulasitiki e-CNC.Ngale kokucushwa kwethuluzi lomshini ovamile nolwazi lokucubungula, ukuqinisekisa ukuthi singakwazi ukuqeda imisebenzi yokucubungula eyinkimbinkimbi ngesikhathi.

Singakwazi ukukhiqiza izinhlobo ezingaphezu kuka-30 zezingxenye zomshini wobunjiniyela bepulasitiki.Yiba nokuqonda okubanzi kwezici zamapulasitiki ahlukene ukuhlangabezana nokuhlolwa kwakho nokuqinisekiswa kwamamodeli ezandla epulasitiki.

Ithimba lethu lingakwazi ukuphatha amaphrojekthi wokwenza izingxenye zepulasitiki ngokunemba.Lezi zingxenye zenziwe ngokwezifiso ngokuya ngemininingwane yedizayini yakho.

Izinzuzo ze-CNC Machining Yezingxenye Zepulasitiki

Okuhlangenwe nakho kwethu ekwakhiweni kwezingxenye zepulasitiki kanye nokwenza imishini kusenza sikwazi ukuhlonza izidingo ezithile zemikhiqizo ezimbonini ezihlukahlukene futhi sibe nekhono lokuhlangabezana nanoma yiziphi izinselele zokwenziwa kwezingxenye zepulasitiki.Ithimba lethu lonjiniyela lihlome ngemishini yemishini ye-CNC ethuthuke kakhulu, engenza izinhlobo eziningi zezinqubo zemishini futhi lenze uhlelo oluhle kakhulu lokukhiqiza lwezingxenye zakho zepulasitiki.

● Nembe Kakhudlwana

Ukucutshungulwa kwepulasitiki ye-CNC kungahlinzeka ngamakhono okucubungula ngokunemba okubunjwa komjovo noma ukuphrinta kwe-3D okungenawo.Izingxenye zepulasitiki ezenziwe ngomshini nazo azinawo umugqa wokubeka wephrinta ye-3D kanye nomugqa wokuhlukanisa wokubumba umjovo, okuthuthukisa ukubukeka kwengxenye yokugcina.

● Asikho Isikhunta Esidingekayo

Ukucutshungulwa kwepulasitiki ye-CNC kungahlinzeka ngamakhono okucubungula ngokunemba okubunjwa komjovo noma ukuphrinta kwe-3D okungenawo.Izingxenye zepulasitiki ezenziwe ngomshini nazo azinawo umugqa wokubeka wephrinta ye-3D kanye nomugqa wokuhlukanisa wokubumba umjovo, okuthuthukisa ukubukeka kwengxenye yokugcina.

● Idizayini Eguquguqukayo

Izingxenye zingacutshungulwa ngokuqondile kusuka kumapuleti epulasitiki noma imigoqo yepulasitiki, ngakho-ke kulula ukuthi ithimba lonjiniyela liguqule umklamo esigabeni sokukhiqiza ngaphandle kokukhiqiza noma yimaphi amathuluzi amasha, futhi cishe akukho zindleko ezihilelekile ekuthuthukiseni izingxenye.

● Isikhathi Sokushintsha Esisheshayo

Ithuluzi lomshini we-CNC lilawulwa yikhompyutha futhi lingakwazi ukugcina ukusebenza okungu-24/7.Yonke inqubo yokukhiqiza ingafinyelela ukusebenza kahle, ikhwalithi kanye nokulawula inqubo.

● Uhlu Olubanzi Lwezinto Ezisetshenziswayo

Ithuluzi lomshini we-CNC lilawulwa yikhompyutha futhi lingakwazi ukugcina ukusebenza okungu-24/7.Yonke inqubo yokukhiqiza ingafinyelela ukusebenza kahle, ikhwalithi kanye nokulawula inqubo.

Impahla Yomkhiqizo

ABS, PC, ABS + PC, PMMA (acrylic), PA (inayiloni), PA + glass fiber, POM, PP, PP + glass fiber, PVC, HDPE, PPS, PBT, PEEK, PEI(Ultem), Teflon, bakelite , Daiki.

| Ukunemba komshini | ±0.1mm/100mm |

| Usayizi omkhulu wokubumba | 3000*1200*850mm |

| Isikhathi sokulethwa esijwayelekile | 5 izinsuku zokusebenza Beijing isikhathi |

* Ngezingxenye ezisheshisa isikhathi sokulethwa noma ezeqile usayizi wengxenye enkulu, sicela uthinte[shixiao_qiu@cd-geekee.com]

| Zonke izinto zokwakha: | Incazelo: | |

| PC | Amandla omthelela amahle kakhulu, izakhiwo zemishini ezisezingeni eliphakeme, amandla aphezulu kanye nokuqina, ukuzinza okuhle kwe-dimensional, ukuhleleka okuhle, kanye nezakhiwo zikagesi ezinhle. | Funda kabanzi |

| I-POM | Ukumelana nomthelela okuhle kakhulu nokumelana nokukhasa, amandla aphezulu kanye nokuqina, i-coefficient ephansi, ukusebenza kahle okuhle kakhulu, ukuzinza kwe-dimensional, ukumuncwa komswakama ophansi. | Funda kabanzi |

| Inayiloni | Izakhiwo ezinhle zemishini, ukumelana nokushisa okuhle kakhulu, ukumelana nokugqoka, ukumelana nokugqwala okuphezulu, isisindo esilula, amandla aphezulu, ukuqina okuhle. | Funda kabanzi |

| I-PCPMMA (Acrylic) | Izakhiwo ezinhle kakhulu ze-optical, ukumelana nokuklwebheka, ukucwebezela okuhle, ukubekezelela okuphezulu kwe-UV, amandla amahle okugoba. | Funda kabanzi |

| I-ABS | Ukumelana nomthelela okuhle kakhulu, amandla aphezulu, ukuqina okuhle, ukunamathela okuhle, ukusebenziseka okuhle kanye nezindleko eziphansi. | Funda kabanzi |

Plastic CNC Processing Technology

| Isinyathelo 1 | Ukulungiswa kwefayela lekhodi ye-G |

| Isinyathelo sokuqala ekugayweni kwe-CNC ukuguqula amafayela e-CAD abe olimini umshini ongalusebenzisa, okuyikhodi ye-G. | |

| Isinyathelo sesi-2 | Faka i-workpiece ku-fixture |

| Umsebenzisi ubeka okokusebenza okusikiwe kube usayizi othize phezu kombhede wethuluzi lomshini.Ngokuvamile, i-workpiece yempahla ihlale ibizwa ngokuthi i-blank noma i-workpiece.Khona-ke sekuyisikhathi sokufaka i-workpiece embhedeni wokucubungula noma ngokusebenzisa i-vise. | |

| Isinyathelo sesi-3 | Khetha ithuluzi lokusika elifanele |

| Njengoba ikhompuyutha ilawula ithuluzi lokusika le-CNC ukuze liye kuzixhumanisi ezisethiwe, ukuma okunembayo nokuqondanisa kwendawo yokusebenza kubaluleke kakhulu ekwenzeni izingxenye ezinemba kakhulu.Isibonelo, ithuluzi elikhethekile le-metering, i-probe, yisisombululo esihle salesi sinyathelo. | |

| Isinyathelo sesi-4 | Ukusika nokukhipha impahla ku-workpiece |

| Khona-ke, i-workpiece ingacutshungulwa.Ithuluzi lomshini lisebenzisa amathuluzi okusika angochwepheshe futhi lizungeza ngesivinini esikhulu ukuze lisuse izinto ezibonakalayo kucezu lokusebenza.Kodwa-ke, esinyathelweni sokuqala, umshini ususwa ngesivinini esiphansi nokunemba ukuze uthole cishe i-geometry. | |

| Isinyathelo sesi-5 | Uma kudingekile, flip workpiece |

| Kwesinye isikhathi, imodeli ayiboni zonke izici ngokusetha okukodwa kwethuluzi lokusika, ngakho-ke ucezu lokusebenza ludinga ukuphendulwa. |

Case Reference

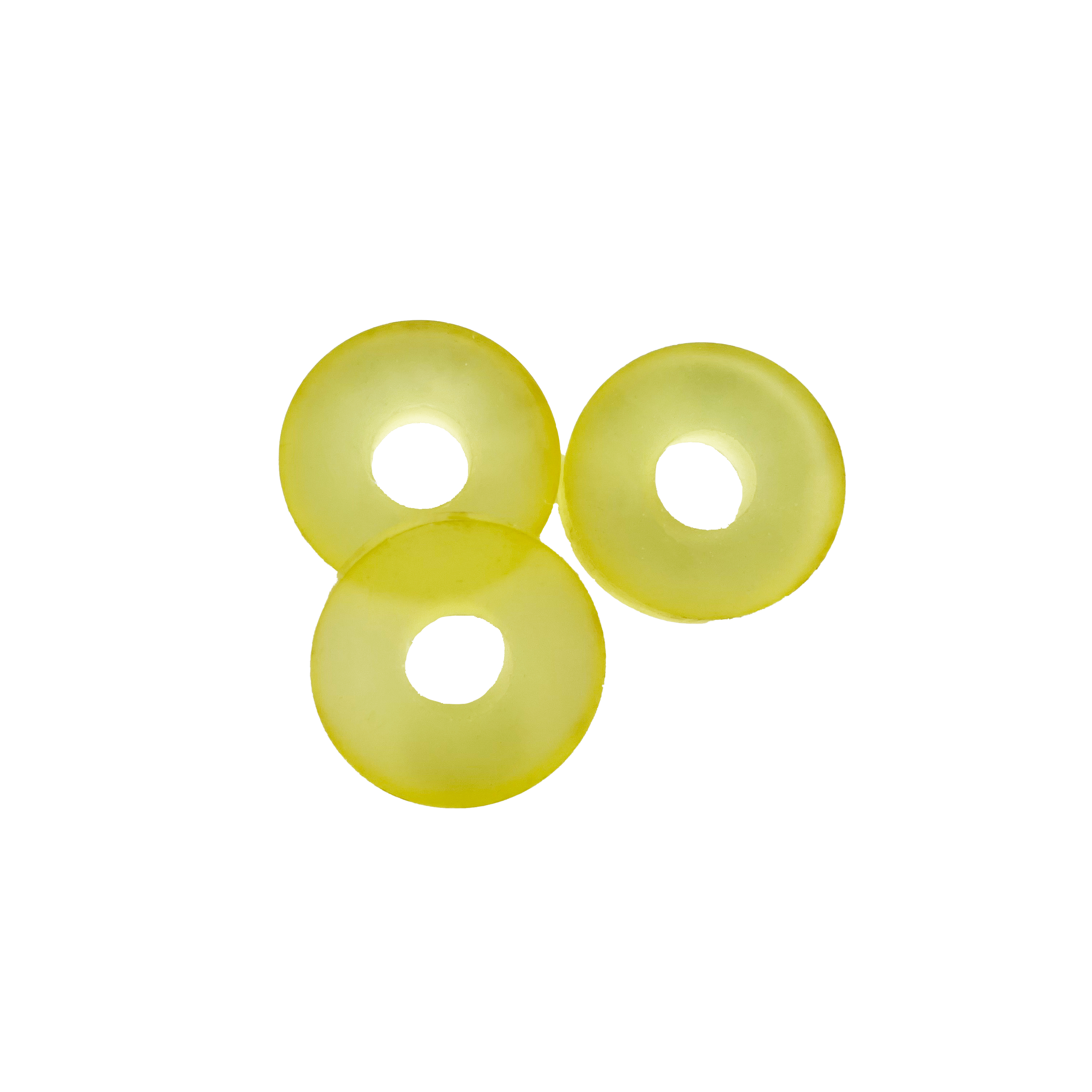

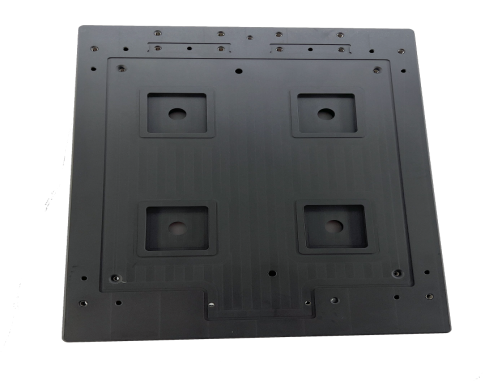

Izigaba zemikhiqizo

-

wechat

-

Whatsapp

whatsapp